- Brands

- Alderdice Brassfounders

- Areta

- Balboa

- Betts

- CMG

- Davies Pumps

- Ebara

- ebmpapst

- Fasco

- Global Water

- Hascon

- HW Ventilation

- HydroGenie

- HydroPak

- Icar

- Jung

- Laing

- Marathon

- Mosswyn Air

- Multi-Wing

- Nicotra Gebhardt

- Onga

- Pentair

- Polyslab

- Portapac

- Shurflo/Jung

- SwitchGenie

- Tecnoplastic

- Telemecanique

- Tellarini

- Torin

- Watertec

- Watkins

- Wellmate

- Zeihl-Abegg

- Products

- Applications

- Where to Buy

- About

- Resources

- Contact

- Blog

Argon blog

Bringing you over 70 years of industry knowledge and advice for the pump,

fan and electric motor industry in New Zealand and the Pacific Islands.

Proven solutions through experience.

Subscribe

- Fan's (5)

- How-To (4)

- Booster Pumps (3)

- Water Pressure (3)

- Blowers (2)

- Davies Pumps (2)

- EBM-Papst (2)

- Multi-Wing (2)

- Pump Control (2)

- ZIEHL-ABEGG (2)

- Case Study (1)

- Engine Cooling (1)

- Engine Cooling Fans (1)

- HW Ventilation (1)

- Health & Safety (1)

- Hose, Valves & Fittings (1)

- MVI Series (1)

- Mosswyn Air (1)

- Nicotra (1)

- Pressure Tanks (1)

- Solar Pump (1)

- Solar Pump System Installation (1)

- Water Filtration (1)

What type of valve do I need?

Selecting the most appropriate valve for your system and needs is crucial to guarantee its efficiency, longevity and performance. At Argon, we have a wide selection of products, including high-quality pumps and valves to suit. Different valve types have specific applications and varying functionalities, so it's essential to know this when trying to find the best valve for your application.

Below, we'll look at some of the different types of valves on the market and their specifications. We've also pulled a selection of valves from our quality range to highlight the variety in our collection.

Butterfly Valves

This type of valve utilises a disk-shaped closing mechanism positioned in the centre of the pipe and controlled by a rod passing through the disk. The disk itself is attached to an actuator on the outside of the valve. Turning the actuator rotates the disk and allows the user to control the flow rate.

Butterfly valves are used in applications where space is limited. Unlike gate valves and ball valves, butterfly valves are able to be used for throttling or regulating flow and fully open and fully closed positions. The loss of pressure through a butterfly valve is slight in comparison with the gate valve.

Check out some of our Butterfly Valves used in water applications here.

Ball Valves

Ball valves are another example of an on/off valve function that utilises a rotating part containing passageways through which fluid can flow when the valve is open. The pivoting ball has a bore through it to allow the flow-through. When open, the ball's hole is in line with the flow and closed when it is turned 90-degrees by the valve handle.

A ball valve is a quarter-turn valve, which means that a quick 90-degree turn of the actuator will rotate the ball, block the passageway and prevent flow through the valve. These valves are designed for full-on/full-off operation, not for flow restriction due to the fluid causing potential seal damage when partially open.

Check out our Butterfly-Handle Ball Valves here and the Long-Handle Ball Valves here.

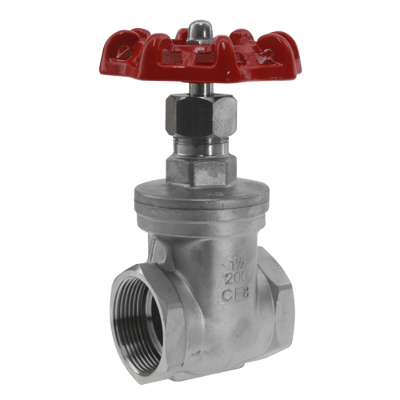

Gate Valves

Gate valves are one of the most common valves used in plumbing applications. They are similar in application to ball valves but are very different in operation.

A gate valve, which is also known as a sluice valve, operates by raising or lowering an internal barrier or gate using a twist-type handle or knob. Gate valves require very little space along the pipeline and, combined with the physical configuration and operation, allows them to be installed in areas with limited space. They are mostly used in applications where the liquid flow needs to be shut off infrequently.

Check out our stainless steel Gate Valves here.

Ball Check Valves

A ball check valve is a very different type of valve that has no external activator or handle. They are designed to be closed off with an internal moving object, a ball, and provide backflow checking inside a piping system.

As the liquid pressure increases, the ball is moved up, allowing the liquid to flow through. Gravity then pulls the ball back into place once the flow pressure decreases.

Check out our Ball Check Valves here.

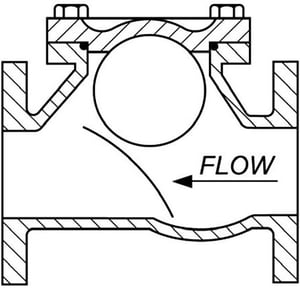

Swing Check Valves

Swing check valves are the most common type of valve used in water and wastewater pumping systems. As the name suggests, these contain a mounted disc that swings on a hinge or shaft. The disc swings off the seal seat as the forward flow starts and drops back when the flow stops to block any reverse flow. A typical example application would be on the outlet side of a pump to protect it from backflow. Metal or rubber seat options are available depending on the application. You can install these valves in horizontal or vertical applications where backflow prevention is required.

Check out our Swing Check Valves here.

Spring Check Valves

Spring check valves are similar in application to swing check valves. As discussed above, swing check valves prevent backflow in systems with a swinging or hinged disc. Spring check valves also prevent reverse flow, in this case utilising a spring-loaded plunger. These valves are used in clean water applications with no debris, leaf litter etc., to jam under the spring-loaded plunger seal.

Check out our Spring Check Valves here, which include plastic, brass and stainless steel options.

The range we have discussed is just a small selection of the types of valves available at Argon. You can check out the rest of our range here.

To ensure you select the correct valves for your application, please get in touch with our team via email here or via the Live Online Chat, and we will be happy to help.